The TH-Series briquettes valuable materials like wood, biomass, metal, or paper. For reliable and economical volume reduction. The TH 1500 briquette press compresses material within a matrix. The hydraulic axial piston pump uses a 30 kW motor and produces 7 briquettes per minute. The throughput weight depends on the material itself. The TH 1500 can be built with a 1,4002 mm hopper, which can also be used for temporary storage of scrap material.

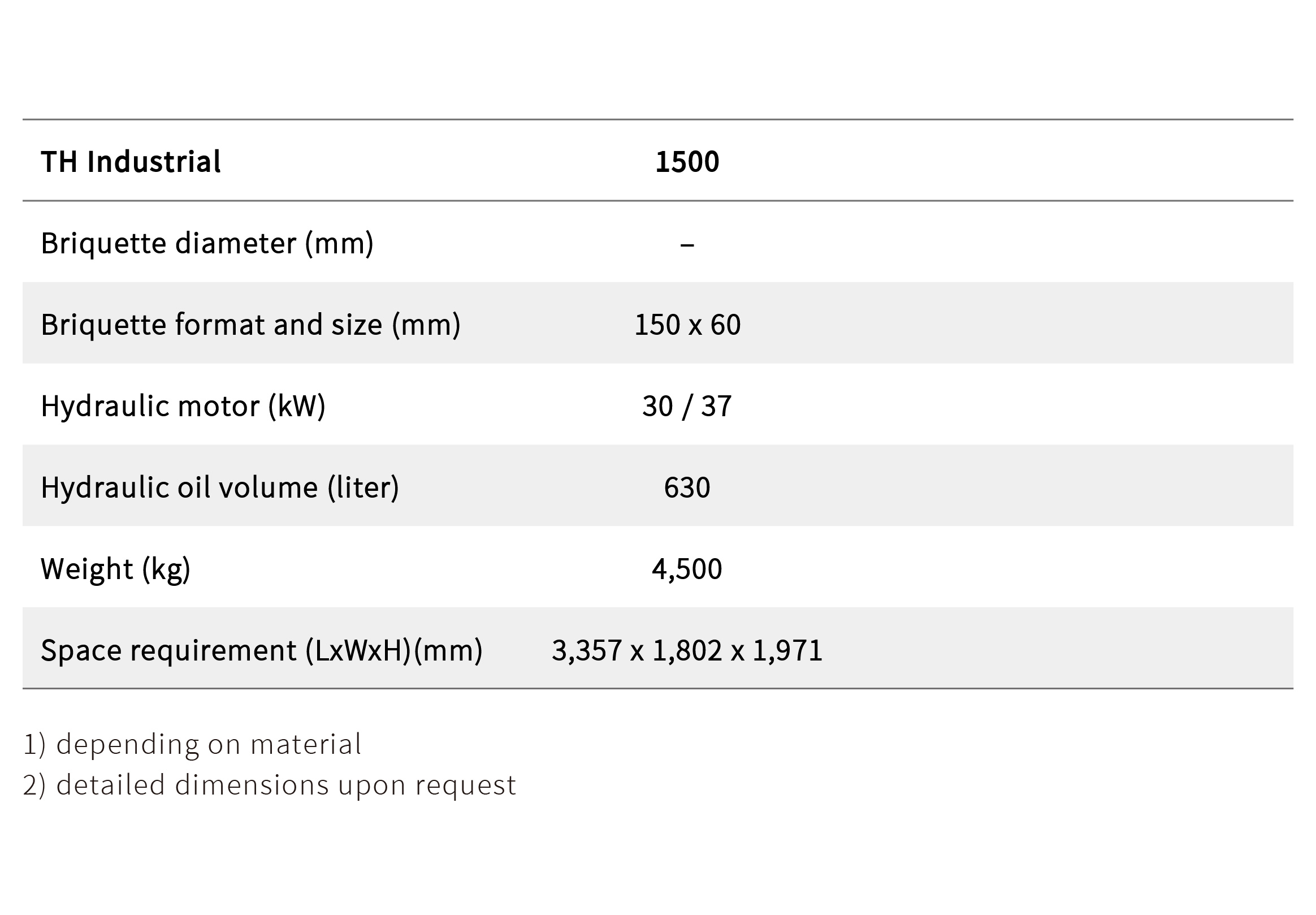

| TH Industrial | 1500 |

| Briquette format and size (mm) | 150 x 60 |

| Hydraulic motor (kW) | 30 / 37 |

| Hydraulic oil volume (liter) | 630 |

| Weight (kg) | 4,500 |

| Space requirement (LxWxH)(mm) | 3,357 x 1,802 x 1,971 |