The TH 800 M briquette press was designed specifically with metal applications in mind. This machine allows for the briquetting of all types of metal shavings, chips, and turnings. Briquetting these materials into dense briquettes adds significantly to their resale value. Not only that, but this machine makes it possible to recollect valuable cutting fluids and emulsions for reuse. A tray and pump is located below the machine to make the collection of these liquids possible. The briquettes that are created can be smelted immediately, resulting in less slag and a higher material recovery rate.

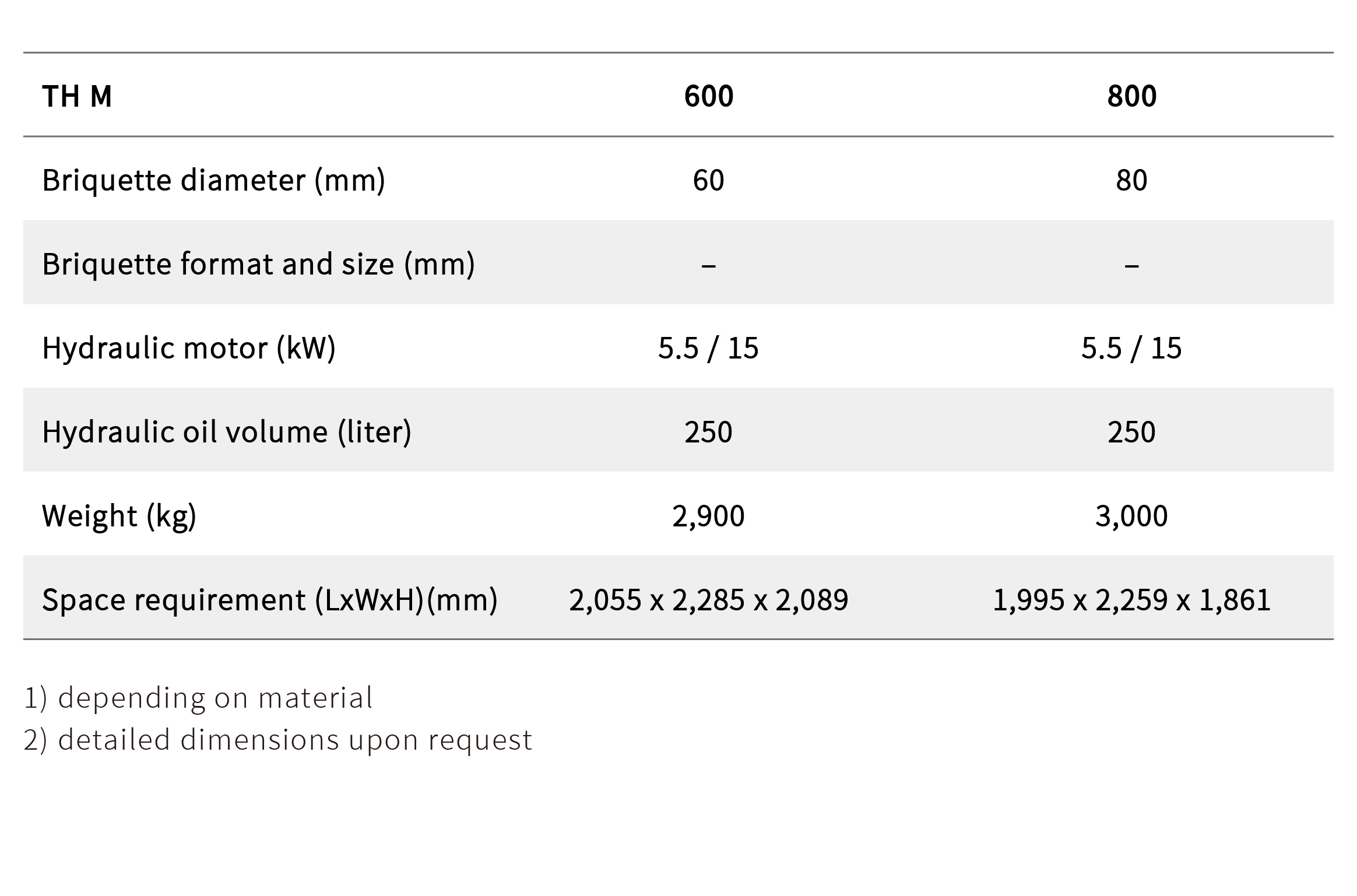

| TH M | 600 | 800 |

| Briquette diameter (mm) | 60 | 80 |

| Briquette format and size (mm) | – | – |

| Hydraulic motor (kW) | 5.5 / 15 | 5.5 / 15 |

| Hydraulic oil volume (liter) | 250 | 250 |

| Weight (kg) | 2,900 | 3,000 |

| Space requirement (LxWxH)(mm) | 2,055 × 2,285 × 2,089 | 1,995 × 2,259 × 1,861 |