The WL 4, WL 6 and WL 8 single-shaft shredders have proven themselves to be the classic shredders for wood waste of all kinds, and can be found in thousands of woodworking shops all over the world. The global popularity of this shredder series assures high reliability at a competitive price to performance ratio. These machines set themselves apart from other machines of their size and type due to their robust construction, giving them a longer life cycle. The shredded wood can be discharged into an air conveyor or onto a traditional conveyor. The profiled innovative “V” Rotor is made of solid material and mounted on stable rotor bearings. Special blade holders are welded into milled blade pockets around its circumference. The cutting knives are set into these and screwed on from the back. This ensures quick and easy blade changing.

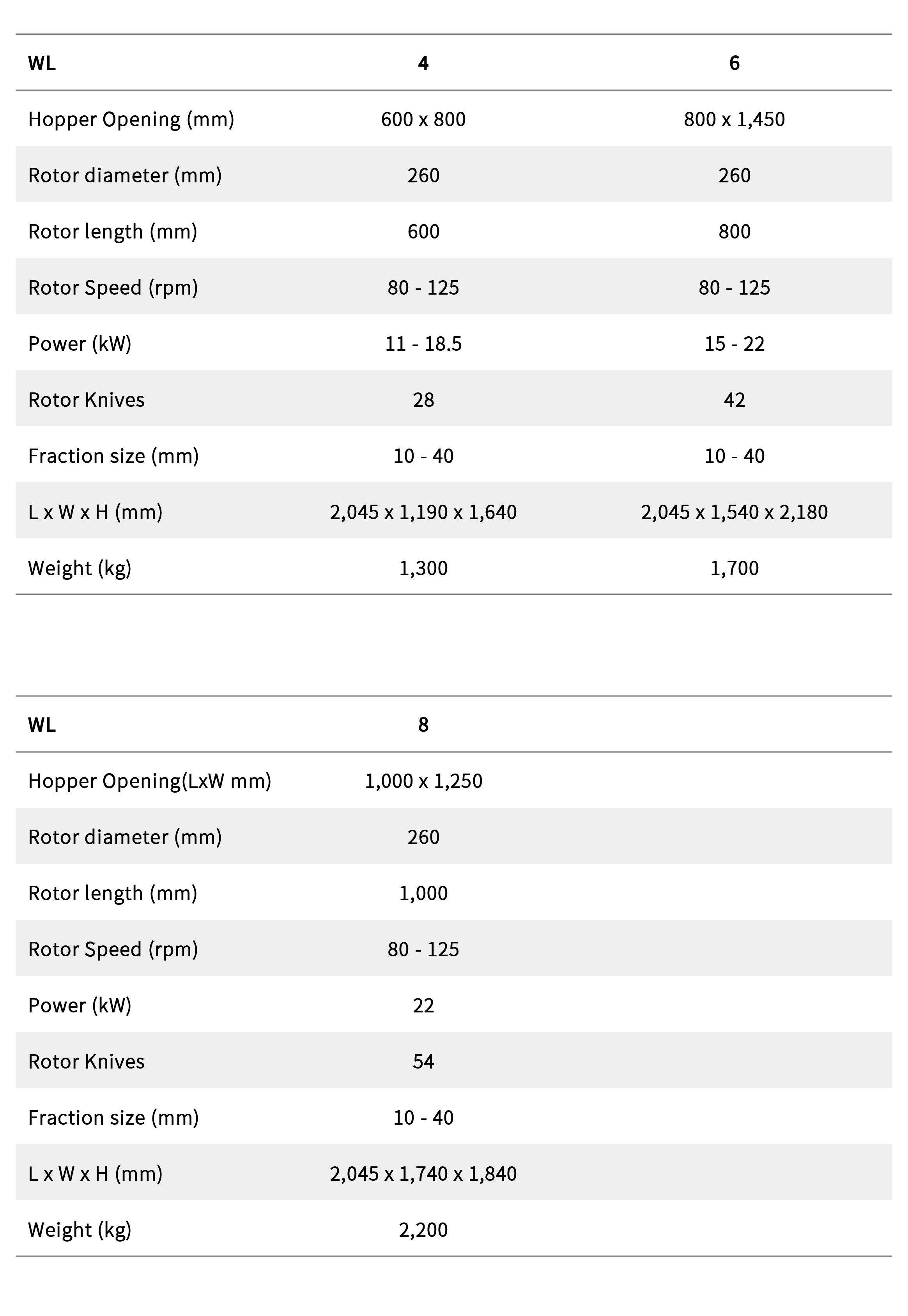

| WL | 4 | 6 | 8 |

| Hopper Opening (mm) | 600×800 | 800×1,450 | 1,000×1,250 |

| Rotor diameter (mm) | 260 | 260 | 260 |

| Rotor length (mm) | 600 | 800 | 1,000 |

| Rotor Speed (rpm) | 80 – 125 | 80 – 125 | 80 – 125 |

| Power (kW) | 11 – 18.5 | 15 – 22 | 22 |

| Rotor Knives | 28 | 42 | 54 |

| Fraction size (mm) | 10 – 40 | 10 – 40 | 10 – 40 |

| L x W x H (mm) | 2,045 x 1,190 x 1,640 | 2,045 x 1,540 x 2,180 | 2,045 x 1,740 x 1,840 |

| Weight (kg) | 1,300 | 1,700 | 2,200 |