Well-engineered technology for wood waste. The WL 10, WL 15, and WL 20 single-shaft shredders are the perfect addition for most shops within the woodworking industry that have large pieces or bulk wood waste the shred. The shredded material can then be transported from the machine via a screw auger, an air system, or a conveyor.

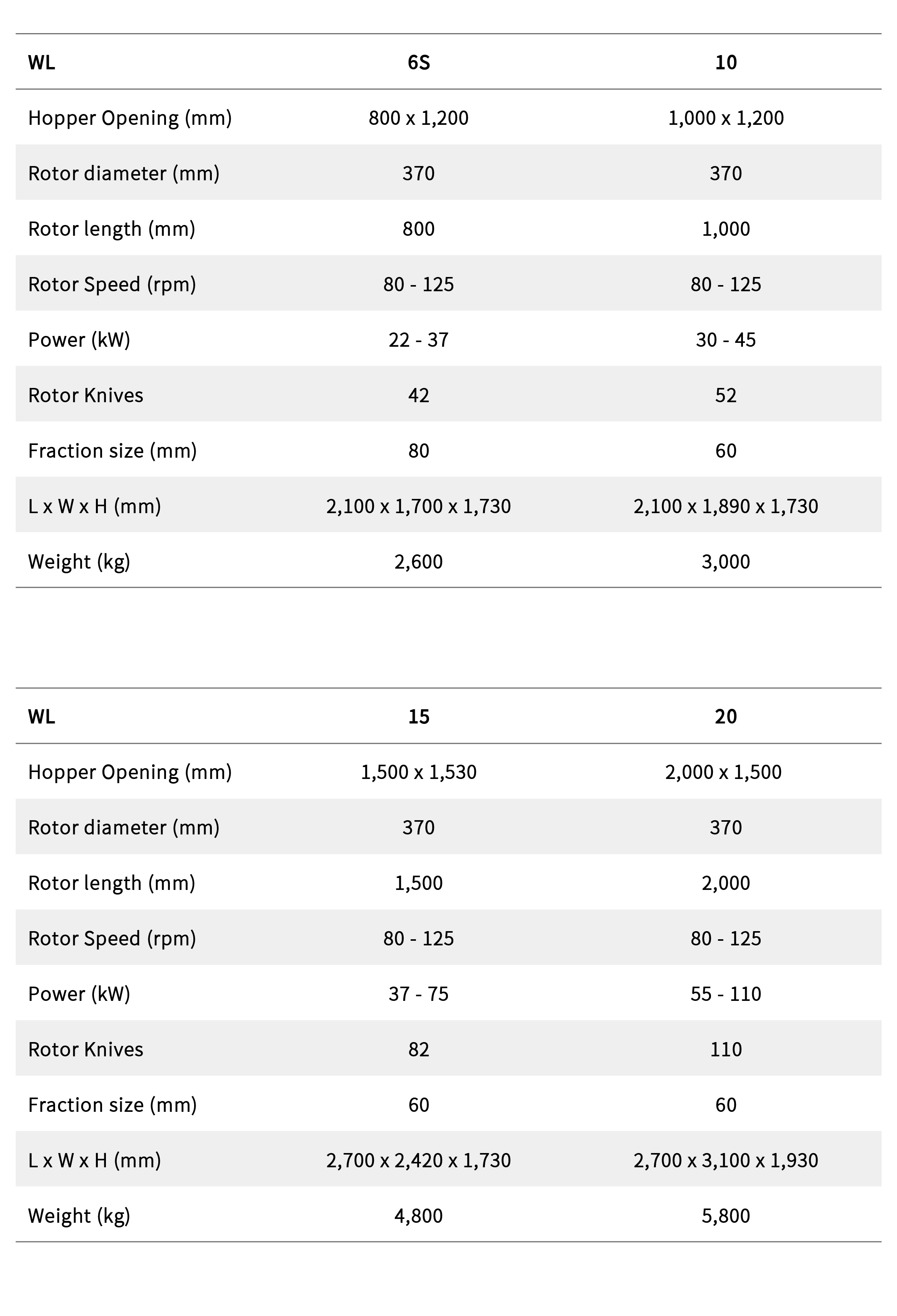

| WL | 6S | 10 |

| Hopper Opening (mm) | 800 × 1,200 | 1,000×1,200 |

| Rotor diameter (mm) | 370 | 370 |

| Rotor length (mm) | 800 | 1,000 |

| Rotor Speed (rpm) | 80 – 125 | 80 – 125 |

| Power (kW) | 22 – 37 | 30 – 45 |

| Rotor Knives | 42 | 52 |

| Fraction size (mm) | 80 | 60 |

| L x W x H (mm) | 2,100 x 1,700 x 1,730 | 2,100 x 1,890 x 1,730 |

| Weight (kg) | 2,600 | 3,000 |

| WL | 15 | 20 |

| Hopper Opening (mm) | 1,500 x 1,530 | 2,000 x 1,500 |

| Rotor diameter (mm) | 370 | 370 |

| Rotor length (mm) | 1,500 | 2,000 |

| Rotor Speed (rpm) | 80 – 125 | 80 – 125 |

| Power (kW) | 37 – 75 | 55 – 110 |

| Rotor Knives | 82 | 110 |

| Fraction size (mm) | 60 | 60 |

| L x W x H (mm) | 2,700 x 2,420 x 1,730 | 2,700 x 3,100 x 1,930 |

| Weight (kg) | 4,800 | 5,800 |