These wood shredders are perfect for the shredding of linear wood waste. This shredder is great for turning solid wood waste into chips. The shredded material is placed into a vibratory infeed conveyor that is the same width as the machine itself. This conveyor feeds the material consistently into the shredder. Horizontal shredders are known within the wood industry and are found in many woodworking shops. In addition to its compact design, the horizontal shredders have a low rotor speed, which helps with noise control. This makes it possible for the machine to be placed directly near the woodworking machine rather than under it for the processing of MDF and solid wood.

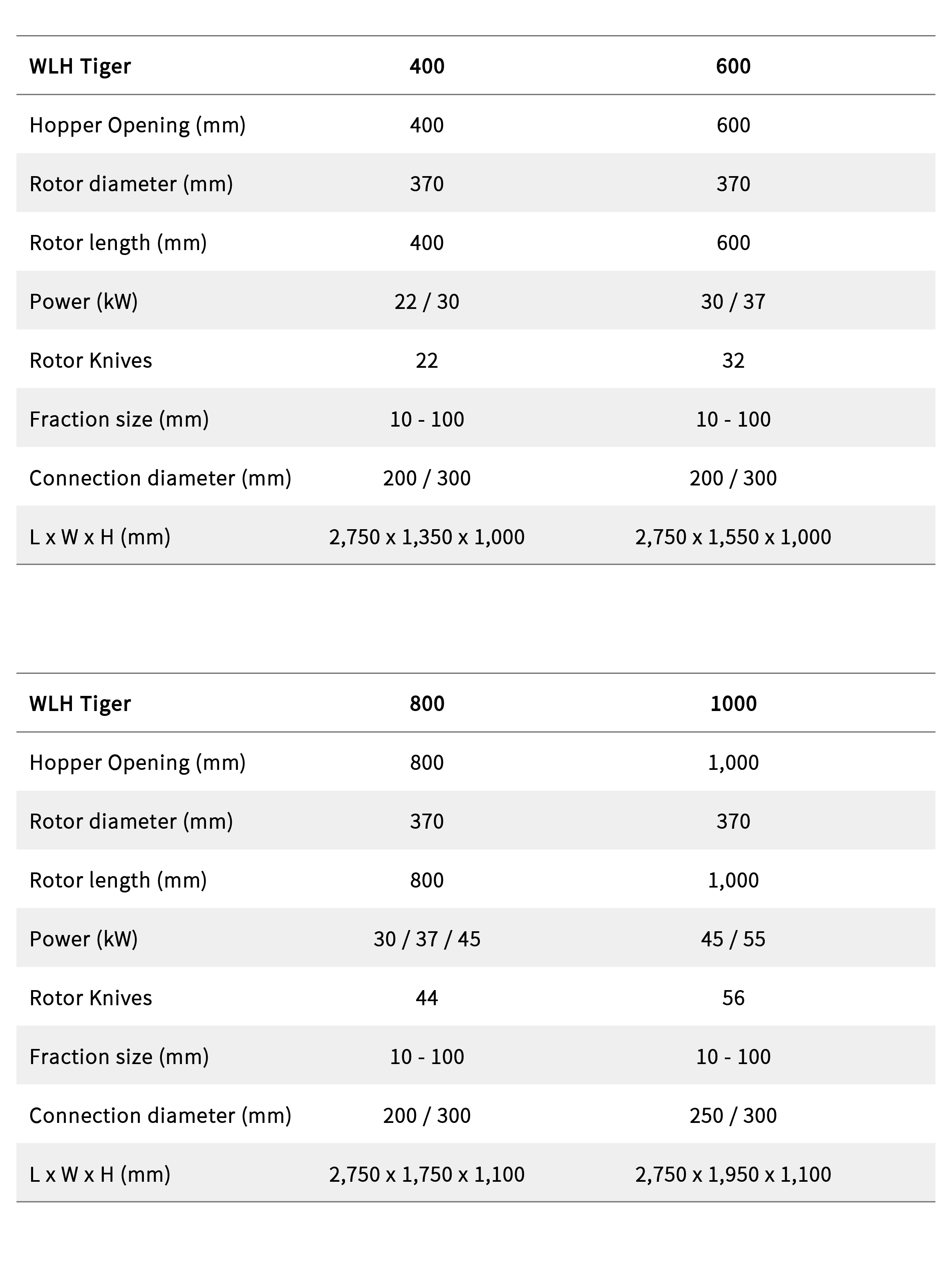

| WLH Tiger | 400 | 600 | 800 | 1000 |

| Hopper Opening (mm) | 400 | 600 | 800 | 1,000 |

| Rotor diameter (mm) | 370 | 370 | 370 | 370 |

| Rotor length (mm) | 400 | 600 | 800 | 1,000 |

| Power (kW) | 22 / 30 | 30 / 37 | 30 / 37 / 45 | 45 / 55 |

| Rotor Knives | 22 | 32 | 44 | 56 |

| Fraction size (mm) | 10-100 | 10-100 | 10-100 | 10-100 |

| Connection diameter (mm) | 200 / 300 | 200 / 300 | 200 / 300 | 250 / 300 |

| L x W x H (mm) | 2,750 x 1,350 x 1,000 | 2,750 x 1,550 x 1,000 | 2,750 x 1,750 x 1,100 | 2,750 x 1,950 x 1,100 |

| Weight (kg) | 1,600 | 2,100 | 2,600 | 3,500 |