The WLK 800, WLK 1000, WLK 1500 and WLK 2000 are designed for high throughput rates and lend themselves to the shredding of almost all types of plastics. You can load these machines with a forklift, by hand, or by using an infeed conveyor, and they come equipped with either an electrical or hydraulic drive.

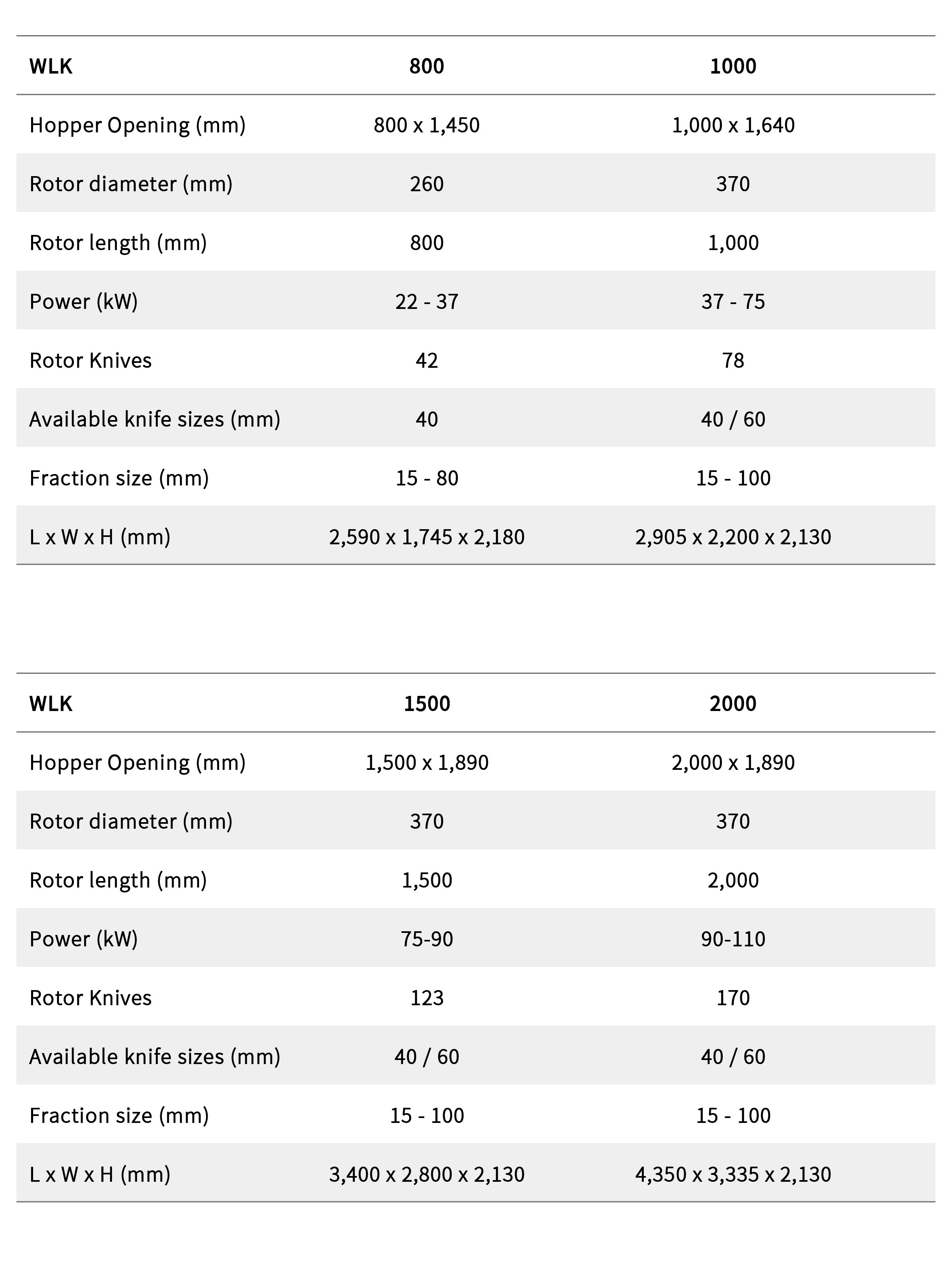

| WLK | 800 | 1000 | 1500 | 2000 |

| Hopper Opening (mm) | 800×1,450 | 1,000×1,640 | 1,500 × 1,890 | 2,000×1,890 |

| Rotor diameter (mm) | 260 | 370 | 370 | 370 |

| Rotor length (mm) | 800 | 1,000 | 1,500 | 2,000 |

| Power (kW) | 22-37 | 37-75 | 75-90 | 90-110 |

| Rotor Knives | 42 | 78 | 123 | 170 |

| Available knife sizes (mm) | 40 | 40 / 60 | 40 / 60 | 40 / 60 |

| Fraction size (mm) | 15-80 | 15-100 | 15-100 | 15-100 |

| L x W x H (mm) | 2,590 x 1,745 x 2,180 | 2,905 x 2,200 x 2,130 | 3,400 x 2,800 x 2,130 | 4,350 x 3,335 x 2,130 |

| Weight (kg) | 2,800 | 3,800 | 6,400 | 9,000 |