The most powerful primary shredder available can process contaminated waste streams and still be moved to multiple locations.

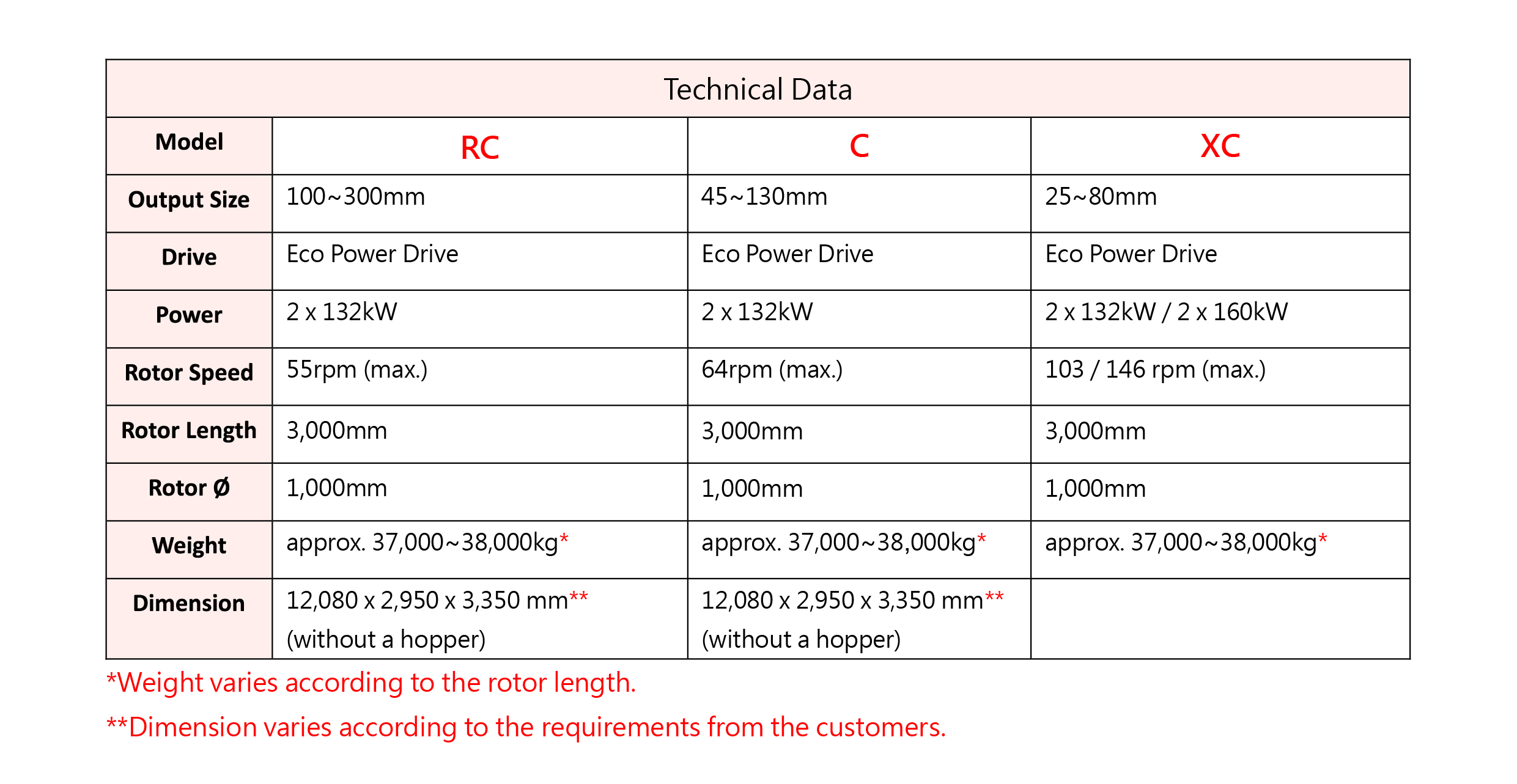

The tracks are powered by electro-mechanical drive allowing the unit to be moved quickly and easily via remote control. There are three different rotor designs available and the

UNTHA Eco-Drive can be equipped with five different gearbox configurations. Screen sizes are available in a variety of different hole sizes and configurations to further ensure your machine can process and produce the exact size end product needed for your particular market(s).