The 4-shaft shredders of the ZM 30 – ZM 50 series are used in woodworking workshops, industry and trade for shredding bulky timber waste such as long boards and pallets, as well as all types of packaging and cartons. The extremely low rotational speed of the shafts of about 25 rpm means that the noise level is restricted to only approx. 76 dB(A). Material is fed from the hopper into the 4-shaft cutting chamber. The design of the hopper can be altered to suit customer requirements. The material is trapped by the high- torque teeth of the cutting discs and shredded. Shredded material then passes through the cutting discs it is discharged through the screen under the cutting chamber.

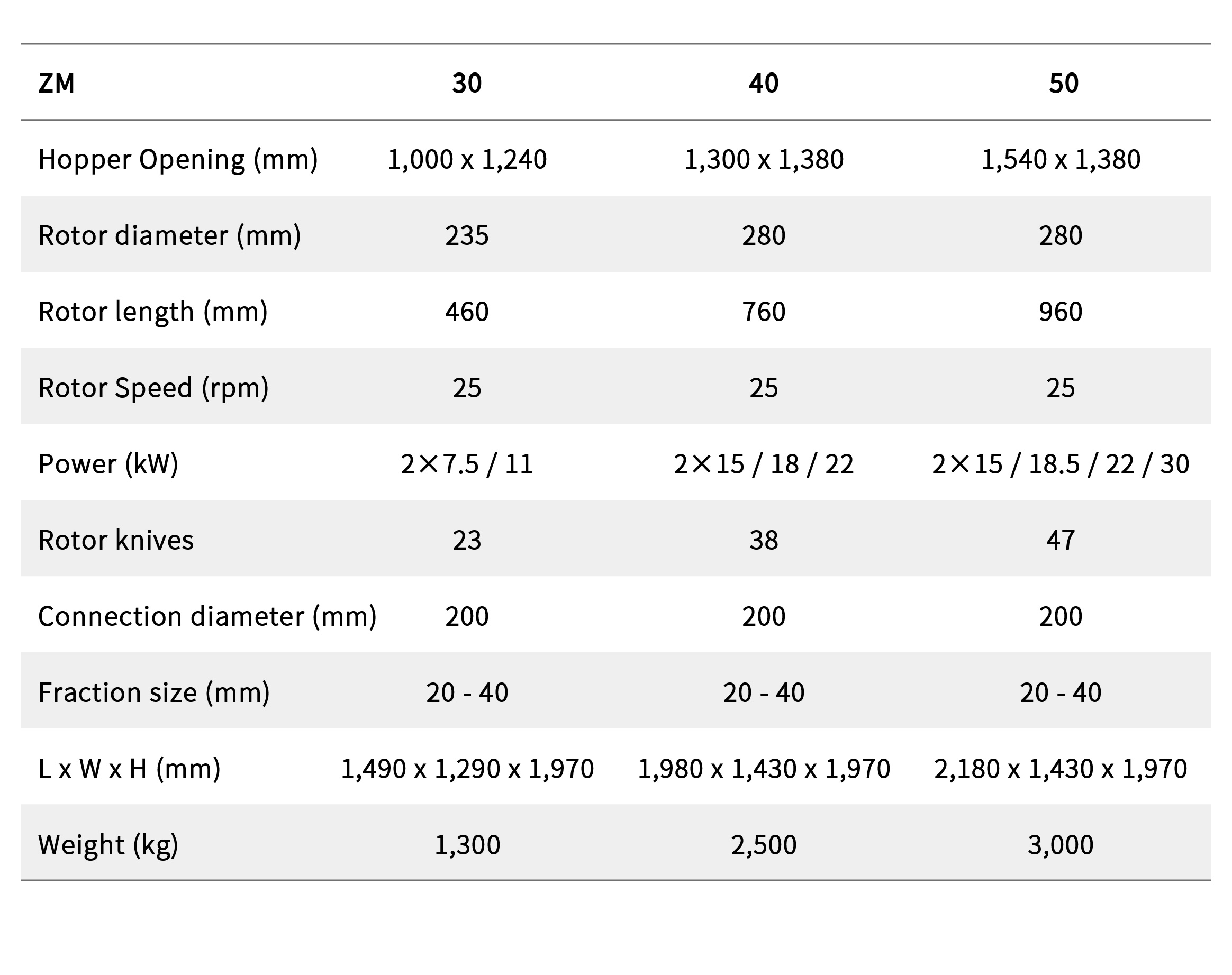

| ZM | 30 | 40 | 50 |

| Hopper Opening (mm) | 1,000 x 1,240 | 1,300 x 1,380 | 1,540 x 1,380 |

| Rotor diameter (mm) | 235 | 280 | 280 |

| Rotor length (mm) | 460 | 760 | 960 |

| Rotor Speed (rpm) | 25 | 25 | 25 |

| Power (kW) | 2×7.5 / 11 | 2×15 / 18 / 22 | 2×15 / 18.5 / 22 / 30 |

| Rotor knives | 23 | 38 | 47 |

| Connection diameter (mm) | 200 | 200 | 200 |

| Fraction size (mm) | 20-40 | 20-40 | 20-40 |

| L x W x H (mm) | 1,490 x 1,290 x 1,970 | 1,980 x 1,430 x 1,970 | 2,180 x 1,430 x 1,970 |

| Weight (kg) | 1,300 | 2,500 | 3,000 |